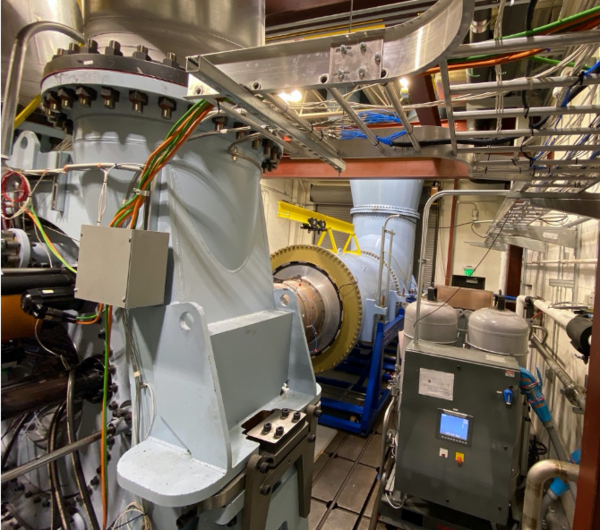

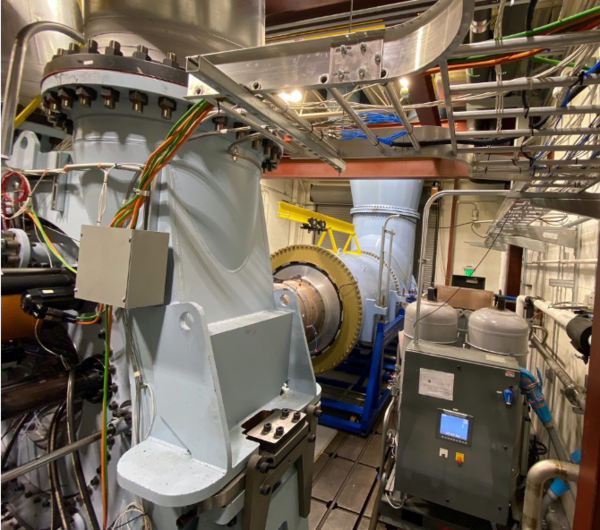

The Notre Dame Turbomachinery Laboratory (NDTL) recently completed a development test campaign of a full-scale, multistage, low-pressure aviation compressor in a 10 MW test cell. The tests included over 600 measurement channels in order to understand the compressor performance in depth. High accuracy instrumentation, detailed and repeated measurement system calibrations, and special care for build-to-build repeatability resulted in a stall margin accuracy of ±0.1% and efficiency repeatability better than ±0.3 points.

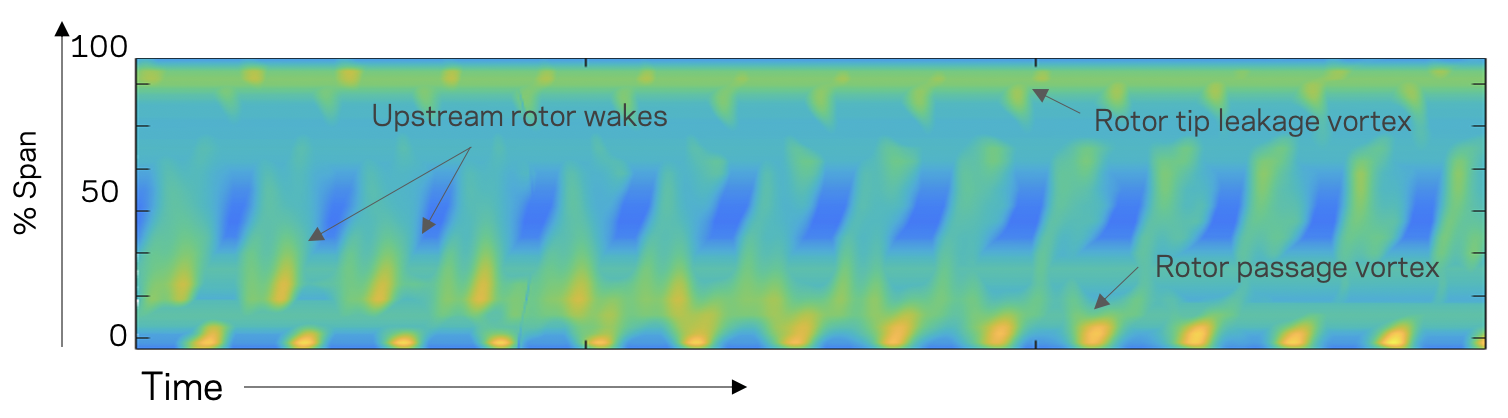

In addition to base performance, the test campaign examined how the compressor flow field changes when the airfoils are subjected to small imperfections. This required measurements of the unsteady pressure behind the affected stage, which were obtained by constructing a custom probe that consisted of a miniature Kulite pressure sensor embedded inside of a Kiel type shroud. The custom probe provided a time-resolved measurement of total pressure; it was then traversed in circumferential and radial directions to construct a whole-field image of the rotor’s aerodynamic performance.

An example result is shown above, featuring individual compressor blade wakes and secondary flows. These measurements were obtained for several different blade alterations in order to study the aerodynamic effects of slightly damaged compressor airfoils.

Inquiries can be sent to ndturbo@nd.edu.

By Chiara Bernardini

Published by Jasmin Avila